Asheville Paint & Powder Coating is dedicated to providing the highest quality powder coated finishes toour customers nation wide.

Powder coating is an better alternative to liquid painting due to its high strength and flexibility with better UV and chemical resistance. Powder coating will protect against road rocks and hazards and still maintain its finish.

Powder coat is an environmentally friendly process. As a comparison, wet paint is flammable, carcinogenic, and full of volatile organic compounds. Because powder coat is applied in dry form electro statically, transfer efficiencies over 90% can be achieved to minimize waste. In special cases, powder that doesn’t end up on the parts can even be reclaimed and reused. As a comparison, wet paint transfer efficiencies can easily drop below 50%, and overshoot goes right into the environment.

Our Services

Powder Coating

Powder coating is a highly durable, environmentally friendly finishing option that outperforms traditional wet paint by a margin of three to one in lifespan. Resistant to fading, chipping, and harsh weather conditions, powder coating offers a wide range of vibrant, top-quality finishes that provide both visual appeal and long-lasting protection. It’s an ideal solution for industrial, commercial, and consumer products requiring a tough, attractive surface.

The powder coating process involves applying a dry mixture of finely ground pigment and resin to electrically grounded surfaces. These charged particles adhere evenly—even in hard-to-reach areas—before being cured in a high-temperature oven, where they fuse into a smooth, continuous coating. The result is a uniform, high-performance finish that enhances durability while delivering a clean, professional appearance.

sandblasting

At Asheville Paint & Powder, our sandblasting services are designed to tackle even the toughest surface preparation challenges. Whether you’re dealing with rust, old paint, corrosion, or grime, our state-of-the-art sandblasting equipment can handle it all—no matter the size of the job. From automotive parts and industrial machinery to metal railings and structural components, we provide thorough, even surface cleaning that leaves your materials ready for a fresh coat of paint or powder coating.

Sandblasting is a crucial step in achieving long-lasting finishes, and we take pride in delivering clean, properly prepared surfaces that meet the highest industry standards. Trust Asheville Paint & Powder to restore and rejuvenate your metal components with expert care and superior results.

screen printing

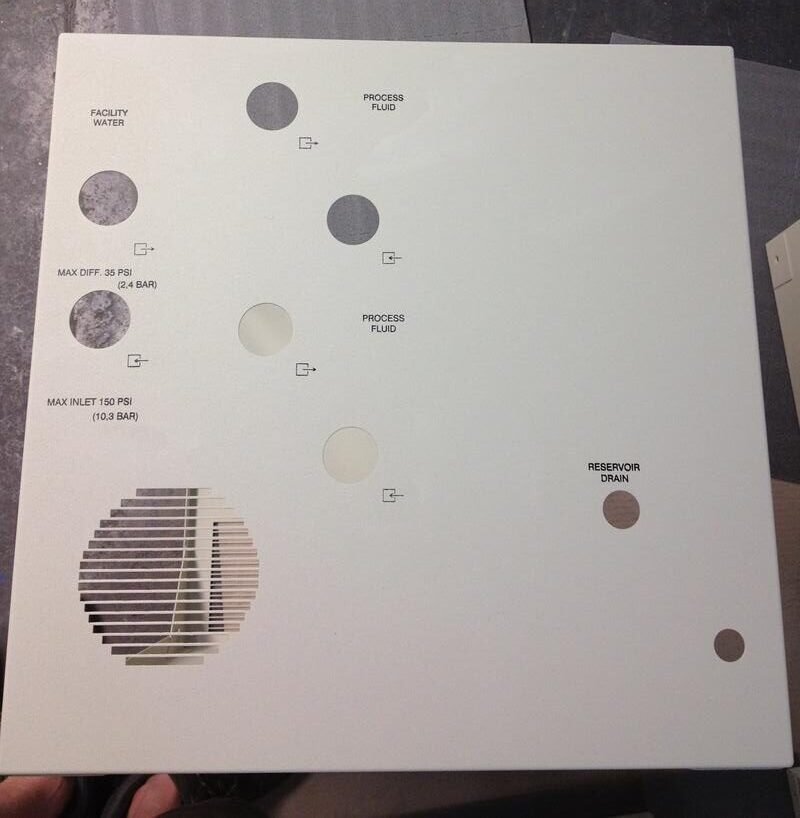

At Asheville Paint & Powder, we offer a full turnkey solution for your industrial finishing needs—including professional screen printing services. From initial sandblasting and powder coating to final branding, we handle every step in-house to ensure a seamless process and exceptional results.

Whether you’re working with bare metal, stainless steel, anodized surfaces, or parts that have already been painted or powder coated, we have the expertise and specialized ink systems to deliver crisp, durable prints. When you need consistent, high-performance screen printing on industrial parts, Asheville Paint & Powder has you covered.

Other services

- Individual part and bulk packaging

- Masking

- Assembly

- Electroplating

- Vibratory

- Buffing

- Polishing

Documentation: Quality/ Preventative maintenance

- Providing all levels of PPAP’S per customer requirements

- Statistical Process Control (SPC)

- Control plans and Flow charts

- Develop standard operating procedures (SOP’s / Work instructions) per customer

- Documented and recorded operator training

- In process and final quality inspections per measured AQL.

- Equipment , documented and daily inspections (Preventive maintenance)

- Inventory control

quality testing lab

- Destructive testing capabilities (hardness testing, chip testing , mil scale testing)

- Salt spray testing

- Adhesion testing (Per ASTM D-3359)

- Film thickness

- Cure

- Gloss meter

- Capability studies (with supporting data)

quality control

APPC is strongly committed to providing products and services that meet or exceed customer expectations. To accomplish this, Quality has been incorporated into all aspects of our business assuring the highest value and satisfaction for our customers, employees and shareholders.

We will produce and deliver products that provide the optimal benefit with a passionate focus on customer needs and desires. These products will be safe, effective and reliable for their intended purposes and will comply with all requirements and regulations for any locale in which we distribute. Our representation of our products and services will always be fair and understandable.

The concept of continuous improvement is a key element in the APPC way of life and is embraced by the company management and employees as well as our external suppliers. Improvement in our products, services and processes may occur in quantum leaps or incrementally, but our efforts will always and forever be to improve and better serve our customers.

APPC Quality Management System embodies these concepts and serves as guidance on how we will achieve our stated goals.

We manage our quality systems using ISO 9001 guidelines and objectives. This has provided the foundation to better customer satisfaction, staff motivation and continual improvements. With this system we are able to provide our customers with a verity of controls and development of new product introductory.